Delivering electricity: The evolving power grid

From Edison to Smart Grid, change is constant

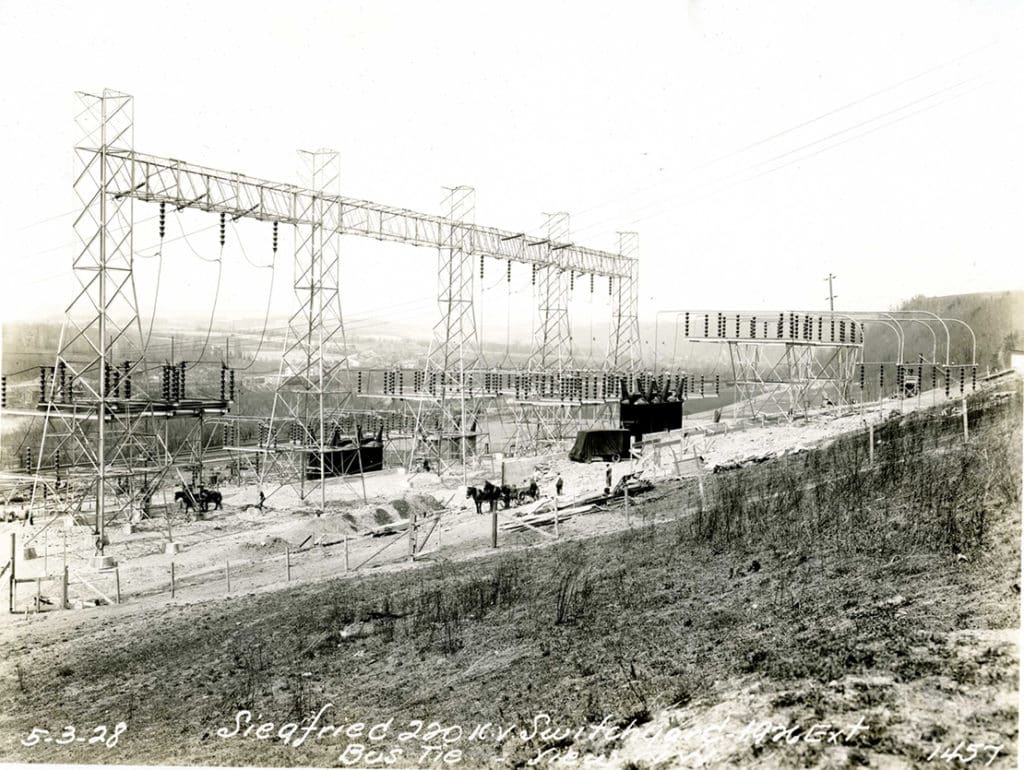

From its humble beginning in 1882 at Thomas Edison’s Manhattan generating station to today’s vast network of more than 2.7 million miles of power lines, the American power grid has always delivered electricity to power our world.

Electric current itself hasn’t changed. It’s still the flow of electrons through conductors.

How it gets delivered, how it’s managed and how outages get fixed, is a different tale.

A lot has changed since Edison’s early days nearly 140 years ago and since Pennsylvania Power & Light Co. was born in 1920.

There is a lot of change still to come with the growth of distributed energy resources like solar and wind power, smarter and more efficient grid operations, and more.

Today’s PPL Electric Utilities grid covers a land area larger than New Jersey, with 50,000 miles of power lines serving 1.4 million customers in all or part of 29 counties in central and eastern Pennsylvania.

Today’s customers benefit from a grid that’s more reliable than ever.

It also is a grid vastly improved by digital technology, by data analytics and by tools and systems unrecognizable to line workers and engineers of past generations. Smart grid technology allows remote power switching and restoration, reducing the scope of an outage. Advanced meters send usage data over secure radio networks and enable customers real-time views of how much power they’re consuming. Drones with specialized cameras can inspect power lines and send back real-time data.

Today’s grid is driven by information and technology like never before.

PPL Electric Utilities Engineer Dave Burdyn can attest to that. Burdyn, who started at the company in 1990, recalled when workers used pins on a large paper map to keep track of storm outage locations.

“There were teams of people analyzing where they thought the trouble was,” he said. “I remember guiding crews aided by sheets of line drawings on the front passenger seat of my car.”

“Now we restore power based on information the devices give us. The system can automatically sectionalize itself and restore customers in less than five minutes,” Burdyn said. “That in itself is light years ahead of where we were when I started.”

Burdyn said manually switching grid devices to get customers back in power after an outage has “almost gone the way of the dinosaur.”

He said instantaneous access to information about the grid is a game changer.

“Our data and information systems are so much more powerful than where we were before. There’s more accuracy in it and more efficiency to get everybody where they need to be to restore customers efficiently,” he said.

Burdyn said customer expectations have increased greatly over time but noted the grid also has improved to match those demands.

John Trostle spent 41 years at PPL Electric Utilities, retiring in 2011 from the Distribution Standards group.

Now back working as a contractor in the same group, Trostle said automation has been the biggest factor in grid advancement over the years.

“Being able to know exactly what the load is on a line is probably the biggest change,” he said.

Data in past decades, before the advent of smart grid technology and equipment, was estimated, while today the equipment provides real-time data.

Gone are the days of crews going from manhole to manhole, using electrical probes to gather information for the loading on an underground low-tension network. Today’s network can be accessed remotely to determine real-time loading and maximum loading.

Trostle said PPL Electric Utilities has been a leader in the industry. For example, he said the company was one of the first to implement storm modeling for outages in the 1960s. With today’s equipment, we know who is out and where to look for the trouble.

Smart grid implementation across the service territory, including things like PPL Electric Utilities’ new advanced meters, provides valuable, real-time information about what’s happening on the grid. And Trostle said that dynamic is changing things for the better and benefiting customers.

PPL Electric Utilities Field Supervisor Mike Summers started as a laborer at the former PPL Brunner Island power plant in 1978 and worked his way to journeyman lineman, then to his current supervisory post.

Like others, he pointed to advances in communications and technology as hallmarks of changes in recent decades. Before there were computers in trucks, cell phones and GPS, things were done via radios and regular land lines.

Power restoration was a longer, much more manual process decades ago, he recalled. Workers had to drive to various locations to open or close devices to isolate problem areas, reroute power or restore power after repairs were made.

“Today, we have smart grid and that technology continues to improve,” he said.

Both training and safety also have greatly advanced, Summers said.

“Both will always be vitally important in all we do,” he said. “Time has not changed that focus.”